Specialized in produce cocopeat dewatering machine--Chinese manufacturers

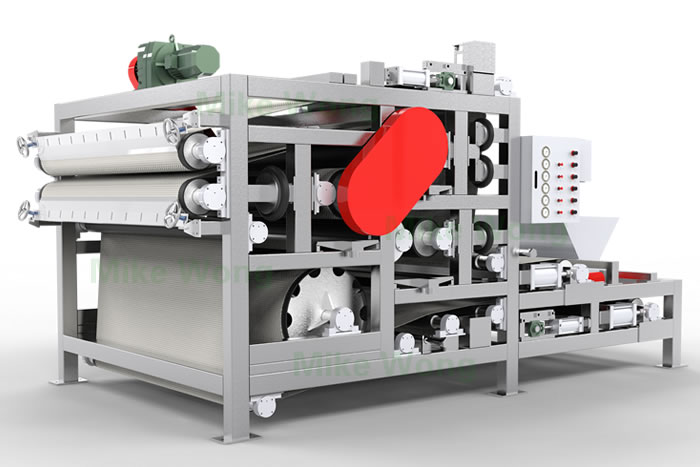

Especially suitable for long fiber slags,such as:cocochips,cocopeat,coconut hust,coco coir pith. The outer part of the roller is made of soft rubber,and the pressureand running speed can be adjusted,then do not destroy material sponge cells,Uotput EC range between 0.3-0.5. Whatsapp:+86 13926231556

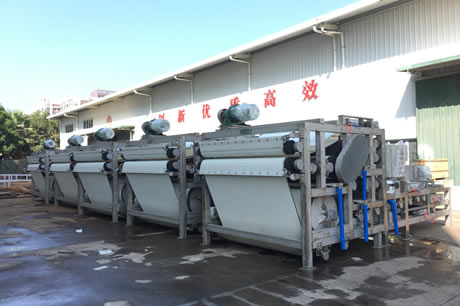

Cocopeat dewatering case

Case lacation:Haikou,hainan,china

Equipment Quantity: One set heavy-duty 3 pairs rollers DYQ1000P3

Output Capacity:above 2 tons per hour

Area occupied:4.5m*1.85m*2.85m(L*W*H)

Intput moisture:85%-92%

Output moisture:50%-55%

The equipment runs automatically without manual operation,After washing,can reduce EC value and moisture content,Increase product prices.Select type based on capacity--The following models can be loaded into containers

- Main motor Power:5.5kw

- UnitPower:13kw

- Long(m):4.5m

- Width(m):1.85m

- High(m):2.85m

- Weight:4.5tons

- Main motor Power:11kw

- UnitPower:21kw

- Long(m):4.5m

- Width(m):2.25m

- High(m):2.85m

- Weight:5.5tons

Coco peat dewatering

Once the husks have been received in production plants they are stored centrally for at least six weeks,after which further processing can begin. The husks are beaten or decorticated to remove the fibres,which leaves us with coco peat.

Washing and buffering

After sieving,the coco peat can be washed by our dewatering machine. Elements which are freely soluble in water,such as potassium,sodium and chloride,are removed. The salt content is reduced to an EC < 1.0 mS/cm [1:1.5 water extraction method]. In addition to this,we can also buffer the coco peat:calcium [2+] is introduced in order to remove monovalent positive ions such as potassium [1+] from the coconut complex. In this way,we remove not only elements which are soluble in water but also elements which are bound to the coconut complex.After dewatering EC value within 0.5

What we can do

Machine Applications

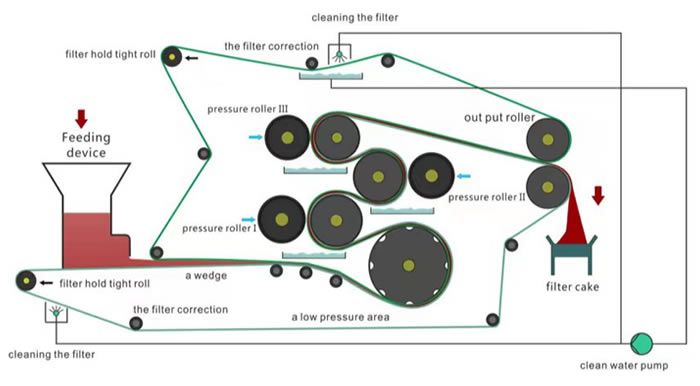

Operation diagram & Advantages

- Automatic feeder,flattening the raw materials to a certain thickness of about 5cm,facilitating the next step to dewatering

- After washing,the raw materials arrive at the first set of pressing and dewatering rollers,and the pressure is adjusted to 0.35Mpa

- The material reaches the second group of squeezing and dewatering rollers,and the pressure is adjusted to 0.4Mpa

- The material reaches the third group of pressing and dewatering rollers,and the pressure is adjusted to 0.5Mpa

- After three sets of roller pressing and dehydration,the EC value of the material decreased to below 0.4 and the moisture content decreased to around 55%

Types,Size and Specifications

Type |

|||

Parameters |

|||

|

Main motor Power(kw) |

5.5kw |

7.5kw |

11kw |

UnitPower(kw) |

11.5kw |

13.5kw |

18kw |

Belt Width(mm) |

1000mm |

1500mm |

2000mm |

Output Capacity(ton/h) |

1.8-2 |

2.2-2.5 |

2.6-3 |

Long(m) |

4.5 |

4.5 |

4.5 |

Width(m) |

1.85 |

2.3 |

2.85 |

High(m) |

2.85 |

2.85 |

2.85 |

Weight(tons) |

4.5 |

5.5 |

7.0 |

moisture content |

50%--55%(After dewatering) |

||

Meet the Team

The founder of Meibang environmental protection equipment

Engaged in international trade has 11 years of experience in equipment sales

Have 13 years experience in mechanical design,gas control design

Guangdong Meibang Holding Group Co.,Ltd.Established in 2011,Located in Huadu district of Guangzhou,China.We are a leading & professional equipment manufacturer for Belt Filter Press,Sludge Dewatering Machine,Residue Squeezing Belt Press.We provide the integrative solution for you about separating and dewatering of solid & liquid.And we also customized design for customers if requested.

Our Company have specialised in developing and manufacturing belt filter press for industrial and sewage sludge dewatering.Through absorbing advance technique from foreign countries and studying carefully for years ,we've designed the vertical & horizontal type of Belt Thickener Filter Press,which is corrosion resisting,low moisture content,low chemical consumption,low operating cost,stable performance ect.As you can see,our product exactly surpass the competitor in terms of performance and workmanship.

![After washing,The salt content is reduced to an EC <0.5 mS/cm [1:1.5 water extraction method].](assets/images/mix/940/2.jpg)